INTELLIGENT SOLUTIONS

FOR YOUR PRODUCT

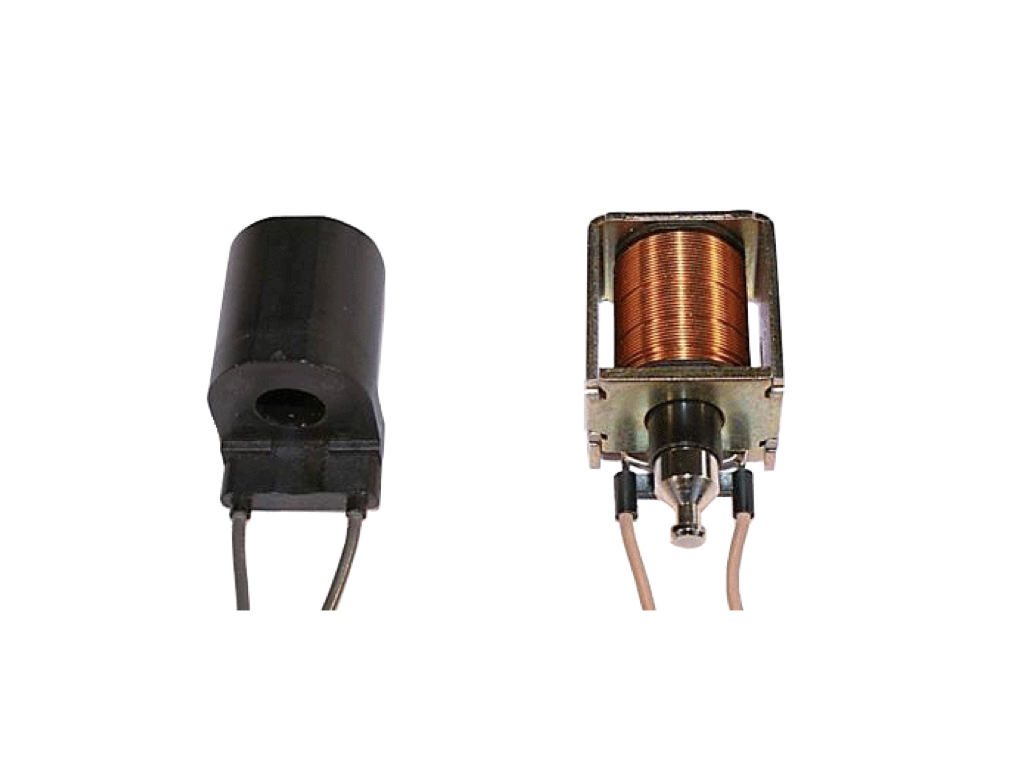

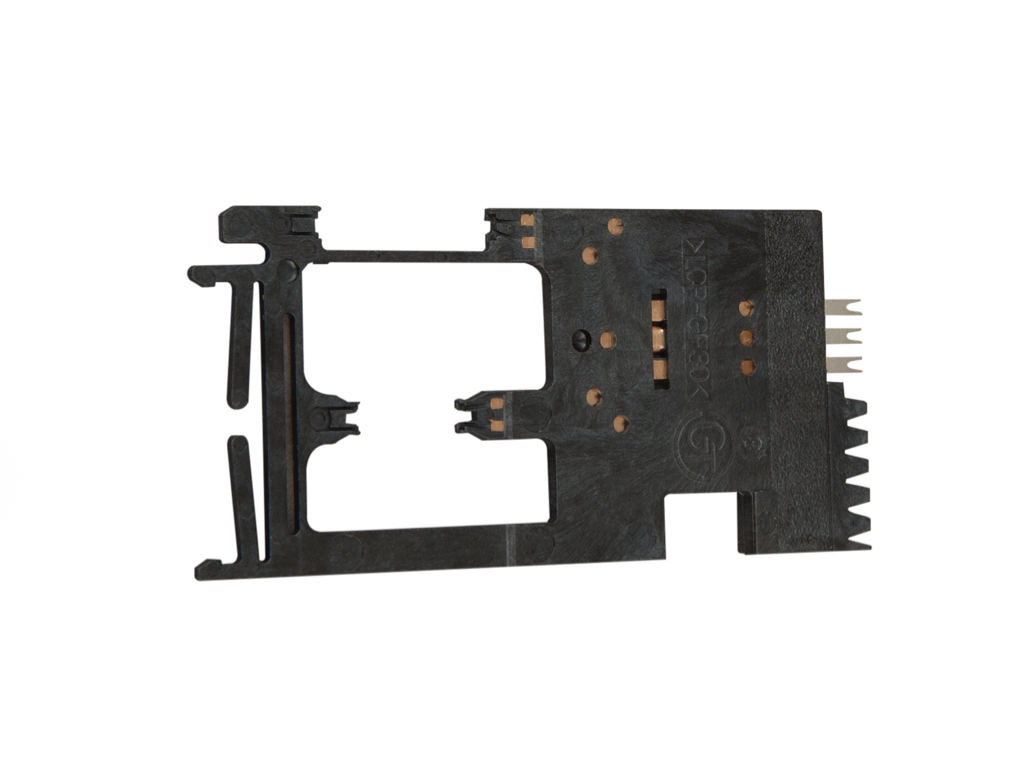

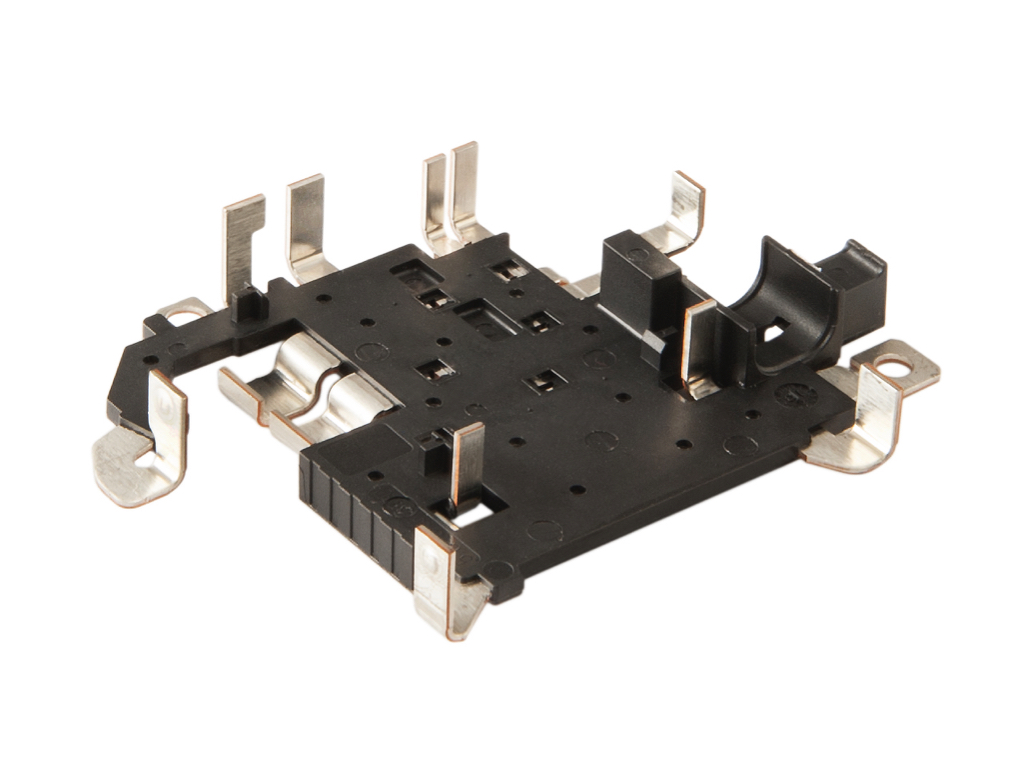

We produce a broad range of plastic products on state-of-the-art injection moulding machines with clamping forces ranging from 12 to 200 t. In addition to processing all known technical thermoplastic materials, we focus on using high-temperature resistant and specially modified plastic materials. Several rotary table machines and vertical machines are used, which enable us to process complicated and delicate inserts and implement difficult outsert mouldings. Our standard machines include entire production cells and automatic handling machines.

Manufacturing of high precision injection-moulded parts made of thermoplastic material

Insert moulding

Outsert moulding

Processing of high-temperature materials up to PEEK in large batches

Ultrasonic sealing of components

The experience and knowledge of our in-house-trained specialized staff ensures robust and stable production processes, based on consistently using statistical-experimental methodology in re-sampling and optimisation. In the spirit of TPM (total productive maintenance), preventive maintenance, systematic inspection as well as tests and calibration guarantee availability of machines and facilities and ensure reproducibility of production processes.

ARE YOU

INTERESTED?

We’ll be pleased to answer any questions about our competences and solutions.

FROM IDEA

TO FINISHED PRODUCT

Custom-made products from a single source GEMA-Technik GmbH develops, designs, produces and checks.